Prosthetic Surgical Templates and Dental Implant Site Time Preparation: An In Vitro Study

Abstract

Numerous types of prosthodontics surgical guides, with and without metallic sleeves, have been found to be useful in clinical studies. The aim of this in vitro research was to compare the time required to complete the surgical procedure with two differently designed surgical prosthetic templates. Ten identical prototype models of mandible based on a CBCT and optical scan of a partially edentulous patient with missing teeth numbers 37, 46, and 47 were prepared and then printed. Five of these models were used for implant site preparation with a surgical guide without metal sleeves and dedicated surgical kit, and the other five models were used for the same procedure performed with a surgical guide with metal sleeves and a dedicated surgical kit. The time of implant site preparation was measured and recorded. Statistical analysis was performed using Student’s t-test for independent samples. Differences between groups were found to be statistically significant (t = −9.94; df = 28; p = 0.0000) with a lower value in favor of the surgical templates without metallic sleeves. Different types of prosthodontics surgical guides, with or without metallic sleeves, seemed to be an important factor which can significantly impact the time of implant site preparation and, therefore, the overall surgical procedure.

Introduction

Dental implantology is a branch of dentistry that aims to restore missing teeth by inserting alloplastic screws (of different materials) into the bone structure (dental implants). Basically, implantology is a rehabilitation procedure aimed at those who have lost their natural teeth. Artificial teeth are designed to replace real teeth that are missing in terms of both aesthetics and chewing function.

The cutting-edge dental implantology techniques allow a permanent rehabilitation of chewing and, in recent years, have aimed to improve aesthetic results. The predictability of these rehabilitations is becoming increasingly high, especially due to the introduction of digital dentistry. Thanks to the advent of digital technologies, it is possible to program, diagnose, and plan a treatment with a completely digital workflow.

Guided implantology is a modern technique for positioning dental implants in patients who suffer from edentulism (lack of one or more teeth) or who have undergone a dental extraction. Using software, the patient’s oral cavity is scanned, creating a 3D model on which the dentist can plan the surgery and preview it. The main advantage of this technique is that it allows the surgery to be carried out exactly as it was programmed on the computer, thus improving mechanical performance and, therefore, predictability. The first step is to conduct an oral examination of the patient; the oral cavity is scanned using a 3D CT scan to assemble the digital model of the dentition. Radiographical examination captures crucial information such as the position of the sensory nerves, the position of the maxillary sinus, and other anatomical points of reference.

This simulation is then sent to specialized centers that create a “surgical guide” used to perform the surgery without affecting the gingiva; the screw is positioned inside the tissues and, consequently, the visible dental crown. Thanks to the precise planning that takes place before the intervention, the procedure is completed quickly. The recent scientific literature, including in vitro studies, systematic reviews, multicenter clinical trials, and randomized controlled trials, leads to the conclusion that using customized, CAD/CAM (computer-aided design/computer-aided manufacturing) surgical guides should be considered the gold standard to achieve high implant accuracy, according to a prosthetically driven treatment plan. Stereolithographic surgical guides are also one of the most popular applications of 3D printing in oral and maxillofacial surgery. D’Souza divided the implant guides into (a) nonlimiting, (b) partially limiting, and (c) completely limiting design, according to the amount of surgical restriction offered by the surgical guide templates. Within these, the completely limiting design group is most advanced and accurate, and it can be divided into three subgroups: (c1) guides with main metal sleeves, (c2) guides without metal sleeves, with plastic only, and (c3) open-frame plastic or metal guides. Most studies have focused on the accuracy of guided surgery using different template designs, concluding that surgical templates without metallic sleeves are more accurate than those where metal sleeves are bonded. In addition, some studies have also reported that the surgery time used for guided implant placement is shorter comparing to the freehand approach. On the other hand, other studies showed several limitations of the guided approach. However, there are no studies comparing the time of surgery with different surgical template designs.

The aim of this in vitro study was to compare the overall time used to prepare the implant sites using two different surgical guides and surgical kits, dedicated to the same taper implants (TSIII, Osstem Implant, Seoul, South Korea ®) but with different template designs: plastic guide with and without metallic sleeves. The null hypothesis was that there is no difference in time between the two different protocols.

Results

A total of 10 surgical templates were printed and then used for the present study. Models were randomly divided into two groups of five models each. Three implants of 4.0 mm diameter and 10 mm length were planned at positions 37, 46, and 47. A total of 30 implant sites were prepared: 15 sites in five models using the One Guide Kit ® (Osstem Implant, Seoul, South Korea 2016 ®) (OGK) and 15 sites in the other five models using the Guide Kit Taper ® (Osstem Implant, Seoul, South Korea 2010 ®) (GKT).

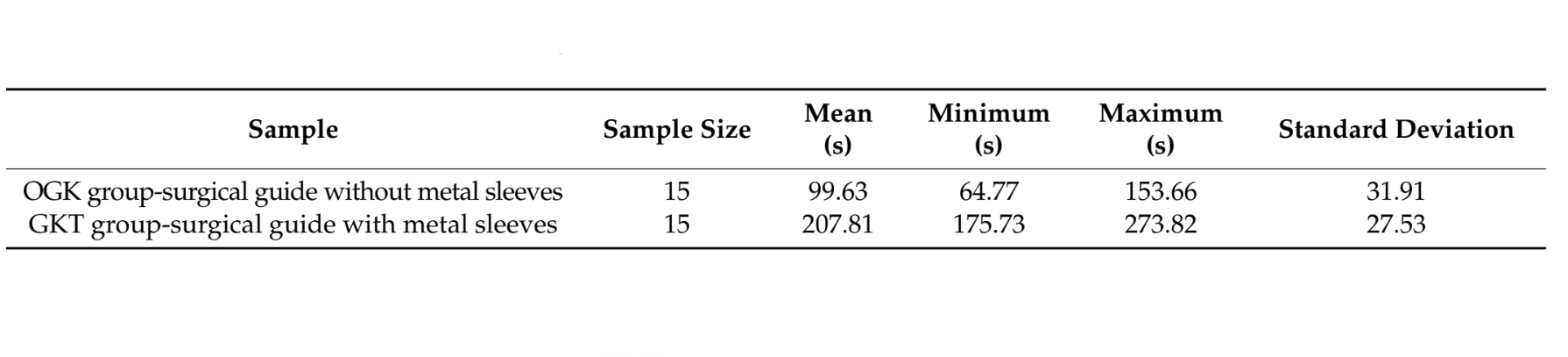

Table 1 presents the results of statistical analysis. The mean time in the test group (without metallic sleeves, OGK) was 99.63 ± 31.91 s, and that in the control group (with metallic sleeves, and GKT) was 207.81 ± 27.53 s.

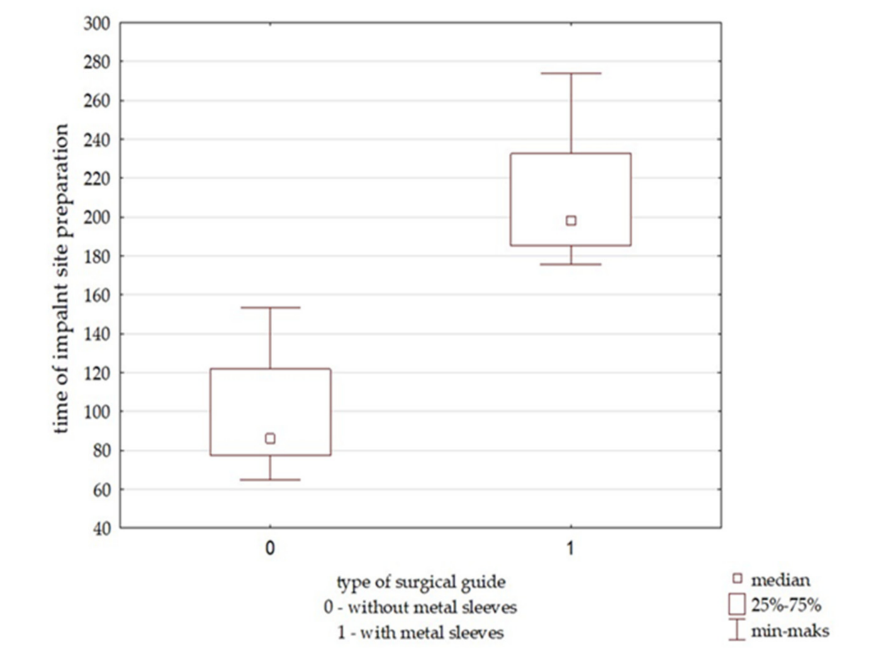

The statistically significant difference between test and control group was verified with Student’s statistical t-test. The t-value of the test was −9.94 with 28 degrees of freedom. The p-value was lower than 0.05 (p = 0.000), proving that preparation time was statistically significantly lower in the OGK group than in the GKT group. Figure 1 shows the differences in terms of the time of implant site preparation in the two groups.

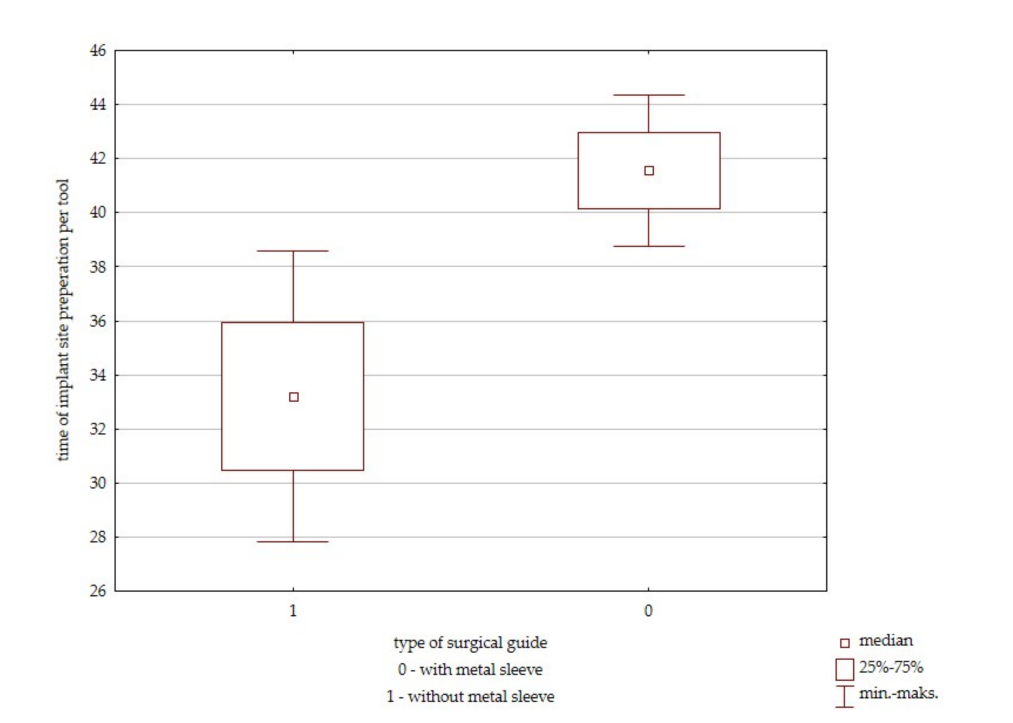

The difference in time per tool for each group was also verified with Student’s t-test. The average time of use each of tool was calculated in both groups, and the data were analyzed. The t-value of the test was −2.70 with 28 degrees of freedom. The p Rafael Delgado-Ruiz-value was lower than 0.05 (p = 0.011), proving that the preparation time per tool was also statistically significantly lower in the OGK group than in GKT the group. The comparison is presented as boxplots (Figure 2).

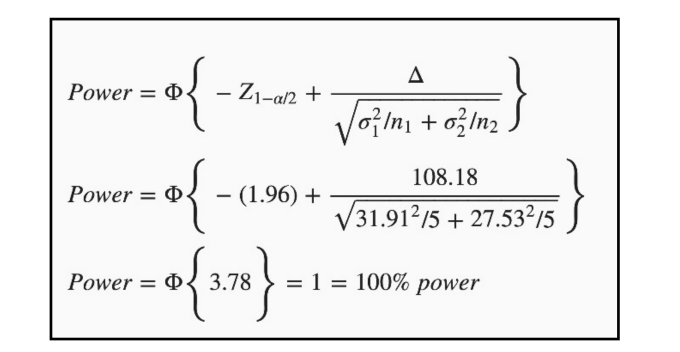

Analysis of the boxplots demonstrated a statistically significant difference between the groups. Post hoc power calculation was performed to evaluate the statistical power of the study. Given the endpoint means and number of subjects, with alpha set to 0.05, the post hoc power was 100% (Figure 3).

Discussion

This study focused on the time required for implant site preparation using two different surgical templates and the corresponding, dedicated, surgical kits. Within the present research, each implant site was prepared in the same conditions (37, 46, 47), such that only differences in surgical tools could influence the site preparation time. The results showed that implant site preparation was significantly shorter using a surgical template without metallic sleeves and OGK. On this basis, the null hypothesis of no difference was rejected. Despite the small sample size and the in vitro nature of the present study, the standard deviation was similar in both groups, which proves that the intragroup differences were similar. This factor contributed to a very high post hoc power of the present study. Investigators have found that the design of tapered drills with a smooth guiding part in OGK allows using each drill diameter, as well as different components included in the kit, with the same diameter tracking part provided by the printed plastic template. GKT drills are cylindrical, with some having a smooth guiding part adjusted to the main metallic sleeve and others not. This induces the need to use additional removable metallic sleeves to reduce the diameter of the main guide sleeve to each particular drill in the sequence. This creates a need to use more tools (drill + reduction sleeve) when working with GKT.

In the present research, one mistake occurred when choosing appropriate tools from the GKT kit, while there were no mistakes with OGK.

The easier protocol of implant site preparation with sleeveless guide design and OGK results in a lower risk of operator error, which might increase the safety of surgical procedures. The reduced number of surgical tools not only reduces the time during the drilling part of the surgery but may also lower the risk of operator or assistant errors and, thus, the total risk of surgery.

Casetta et al. found that the clearance between drills and metallic sleeves incorporated into plastic templates or even the clearance between drills and reduction sleeves may lead to the inaccuracies during surgery. The accuracy of two surgical guide designs and kits (OGK and GKT) was compared in an RCT with 100 implants placed. Within this study, we compared only the time of implant site preparation using exactly the same kit and template design. A total of 41 implants were placed with GKT and metal sleeves incorporated into a plastic guide frame, while 49 implants were placed with OGK with a plastic guide frame only. Surgical templates without metallic sleeves were found to be more accurate in terms of the vertical plan and angle compared to the conventional template with metallic sleeves. Comparing the requirements for the preparation of both kits, the investigators noticed that incorporating a metallic sleeve into a 3D printed frame required 1 mm more interdental space to design the guide has Although this had no effect on our experiment planned at molar sites, it could have clinical limitations when limited interdental space is available, e.g., premolars or lower incisors.

In addition to more space requirements, Cassetta et al. found that placing a prefabricated metallic sleeve within the template can induce errors during the fabrication of a surgical guide, and, as previously mentioned, the clearance margins between the main sleeve and the reduction sleeve for a particular drill and between the reduction sleeve and the drill can result in inaccuracies during surgery. Another issue is the extra cost of dedicated metallic sleeves, as well as the lab work to accurately place and bond them in the guide frame. All of these factors increase the cost of treatment, especially in cases where several implants are planned. Therefore, three-dimensionally printed surgical guides with in-built nonmetal sleeves of smaller diameter have been suggested by Schneider et al. for reducing lateral drill movement and instrument tolerance, as well as the cost. Furthermore, when a plastic-only 3D printed guide frame is used as a surgical template, the device and 3D printing technology used for manufacturing may also be key points for the accuracy. Another advantage of a 3D printed template without a metallic sleeve is the possibility to design a buccal opening to facilitate drilling in the posterior region (limited mouth opening). Nevertheless, so-called side open sleeves have been found to provide lower accuracy comparing to closed plastic sleeves in printed templates, but higher accuracy compared to freehand implantation procedures. On the other hand, side open sleeves without metal incorporated elements may be the only possible design in some clinical situations due to anatomical limitations including mouth opening and interdental space.

Colombo et al., in a critical review based on randomized controlled trials regarding clinical applications and the effectiveness of guided implant surgery, concluded that reductions in surgical time and postoperative pain are discussed during guided implant surgeries. It is important to mention that the study was based on two RCTs and, in both cases, bone or soft-tissue stabilized implant guides were used, which means that patients underwent extensive surgical interventions. In another RCT, higher postoperative pain and swelling at sites treated freehand were found compared to those with a guided approach. The difference in patient postoperative experience in these studies may be based on the range of surgery itself. In general, surgery where the extensive flap is elevated and a guide is seated at the bone surface is more traumatic than mini flap or flapless guided placement of single or multiple implants with a tooth-supported guide. Thus, there could be no significant difference for the patient if extensive surgery is done guided or freehand, whereas there may be significant differences for less extensive surgery. Furthermore, the accuracy of guided implant placement varies depending on if it is a simple or complex surgery. The same time required for accurate guide stabilization with bone anchors during extensive surgery may disappear when comparing the time required to conduct a similar surgery freehand without this process. Nevertheless, the times of main surgery and implant sites preparation may be shorter with a guided approach or even if simple guiding devices are used. Analyzing risk factors for postoperative complications following oral surgery, Shigeishi et al. found prolonged operation duration to be a significant risk factor in patients who underwent oral surgery.

Considering that different surgeries require different times for preparation of the operative field, anesthesia, flap reflections, and template installation and fixation, a guided approach provides increased accuracy during implant procedures.

There were limitations to this study. Accuracy comparison between tested guides and kits was impossible to perform within the in vitro trial. This limitation was based on the study model’s material properties. As the implant site performed in the stiff plastic model according to the manufacturer’s recommendation for hard bone is smaller in the diameter than the implant thread, and as the resistance of the polyamide is very high, it is impossible to place an implant with appropriate torque. During implant placement, applied torque led to immediate destruction of the implant transfer design to be used during guided implant placement. Therefore, to accurately compare two identical template designs and surgical kits in the RCT, it was decided to focus only on the time comparison within this in vitro study. Another limitation is that the drilling time within native bone may differ from drilling in plastic models. However, depending on the bone type or its hardness, drilling procedures at different sites or in different patients can take different amounts of time. It is almost certain that the absolute amount of time required for site preparation in the bone may be different from that in plastic models. Nevertheless, the results of this study suggest that using a sleeveless guide with OGK may significantly reduce the time of implant site preparation compared to a sleeve guide and dedicated GKT. This can be especially important if multiple implants are placed during surgery.

In addition to all the intra-surgical aspects of template-based implant therapies, these procedures are preceded by a careful diagnostic process. A planning phase with the use of CBCT images, scans of oral tissues, and visualization of the final restoration plan may be helpful during patient–doctor communication. Understanding the treatment plan and all its benefits, including lower invasiveness, less pain, better precision, and, as indicated in this study, shorter surgery time with digital supported implant therapy, may be beneficial to reduce fear and anxiety among patients.

Materials and Methods

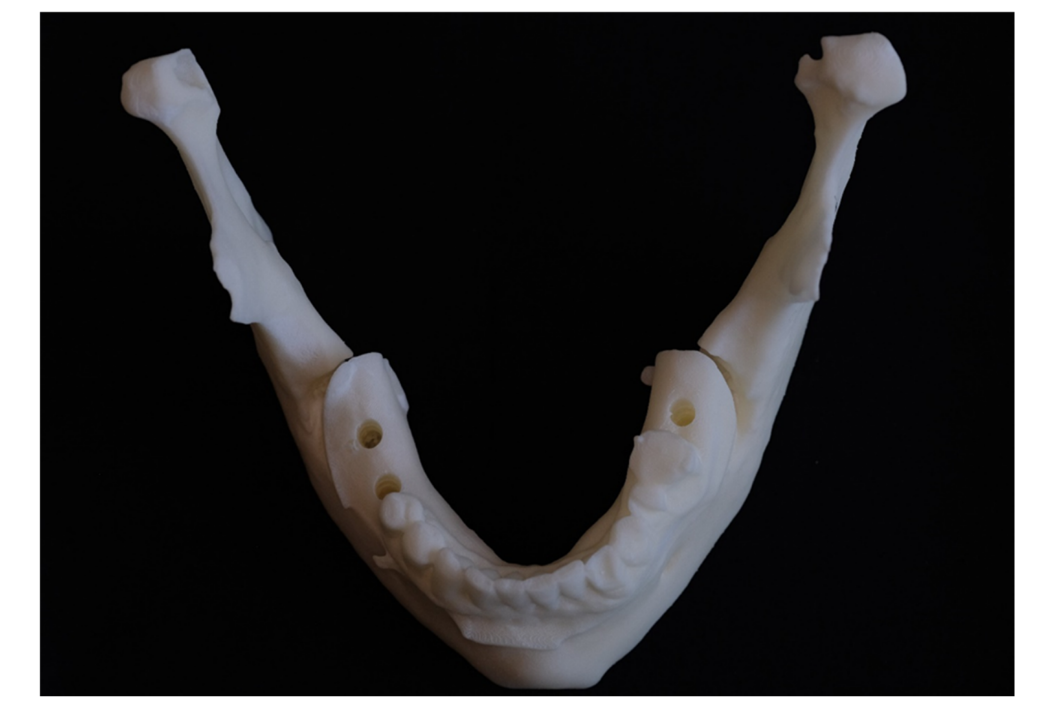

Models for the experiment were created on the basis of previously collected data from a 56 year old partially edentulous man, with missing teeth numbers 37, 46, and 47. The DICOM (Digital Imaging and Communications in Medicine) data of the patient were derived from a previous CBCT (cone beam computed tomography, NewTom 5G XL, CEFLA s.c., Imola, Italy) scan. The stored gypsum model representing the hard- and soft-tissue anatomy was digitalized with a lab scanner (Ceramill Map 600, Amann Girrbach AG, Koblach, Austria), and the data were imported into the DDS-Pro software (JST, Cze˛stochowa, Poland). The digitalized model was saved as an STL (Standard Triangulation Language) file, and then printed using SLS (Selective Laser Sintering) technology and polyamide powder material (SL01, Sondasys, Ogrodzieniec, Poland). An external printing center prepared all the models (Sondasys, Ogrodzieniec, Poland). Figure 4 shows the 3D printed model.

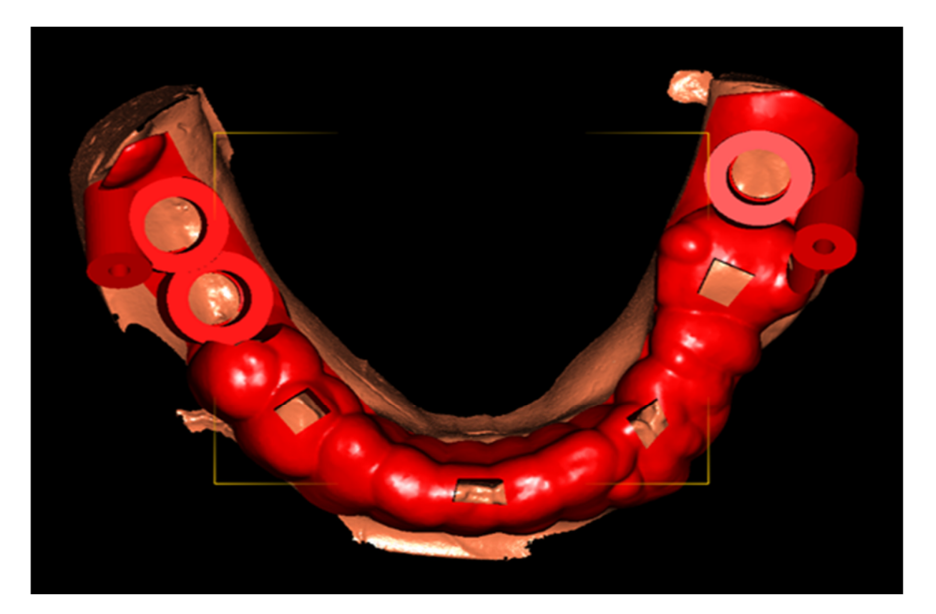

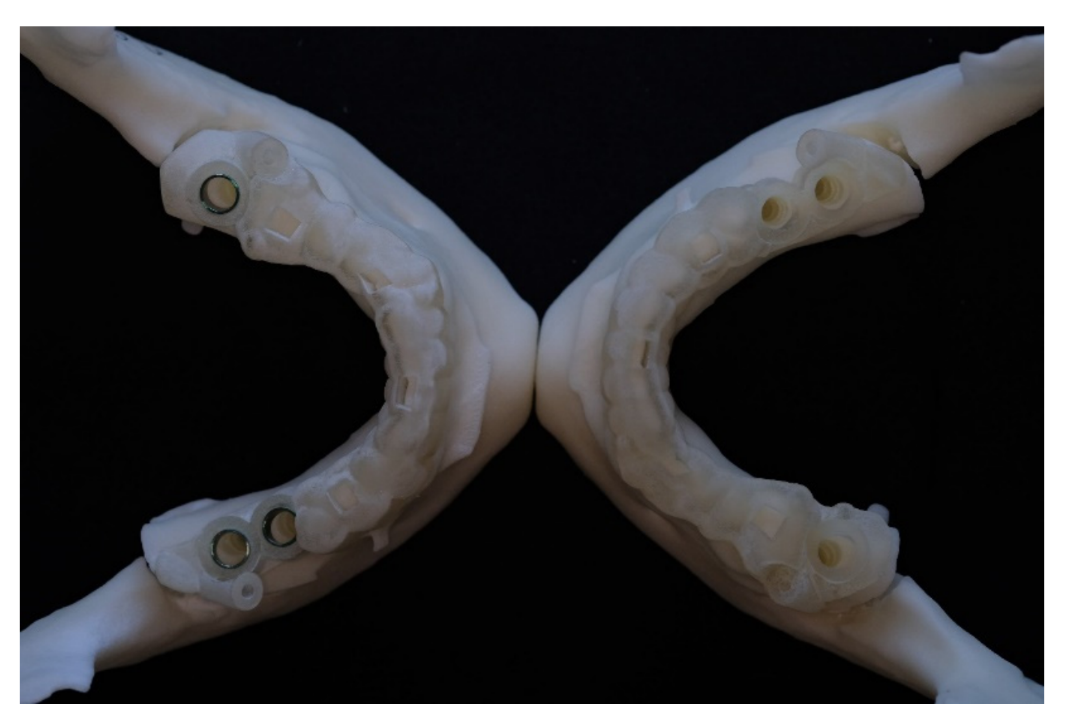

The DDS-Pro software was used to virtually plan implants of 4.0 mm diameter and 10 mm length, in the correct, prosthetically driven positions. Two types of surgical guides (Figure 5) were designed according to the manufacturer’s recommendations, to be used with two different surgical kits, for placement of the same tapered implants (TSIII SA Implants, Osstem Implants, Seoul, South Korea). A surgical template without metallic sleeves was designed to be used with the novel OneGuide Kit (Test group, OGK, Osstem Implants), while a second surgical template was prepared to incorporate metallic sleeves dedicated to 4.0 mm diameter implants (Green metal sleeve, Osstem Implants) with Guide Kit Taper (Control group, GKT, Osstem Implants).

Guides were designed in the same shape, such that the only difference between them was the diameter of the holes, prepared according to the different surgical kit requirements (Figures 6 and 7). The GKT required 1 mm more to incorporate and bond the dedicated metallic sleeve into the surgical guide. Both templates were 3D printed at an external printing center (Natrodent, Łódż, Poland) using multi-jet technology (MP3000, 3D Systems, material: supports S100, guide MP100, 3D Systems, Rock Hill, SC, USA). After printing, the surgical templates were placed in a freezer for a few minutes. This allowed easy removal of printouts from the printer build plate. Once surgical templates were removed from the build plate, the support material was removed in a convection oven at 70°C for 30 min. After that, any remaining support material was removed with a paper towel and an ultrasonic bath at approximately 65°C (5 min). Finally, the surgical templates were rinsed with warm soapy water and dried with a paper towel and dry compressed air. After being checked, the surgical templates were sent for the in vitro test.

All models were randomly divided into two groups. The first group involved the use of a guide with metallic sleeves and the GKT, while, in the second group, the surgical templates was produced without metallic sleeves, to be used with the OGK.

Three implant sites were prepared in each study model, according to the virtual plan and the manufacturer’s instructions. Drilling procedures were conducted by the same expert operator with both surgical kits (Ł.Z.), using the Implantmed surgical device (W&H Dentalwerk Bürmoos GmbH, Bürmoos, Austria) with a speed of 1200 rpm and maximal torque under cold saline irrigation.

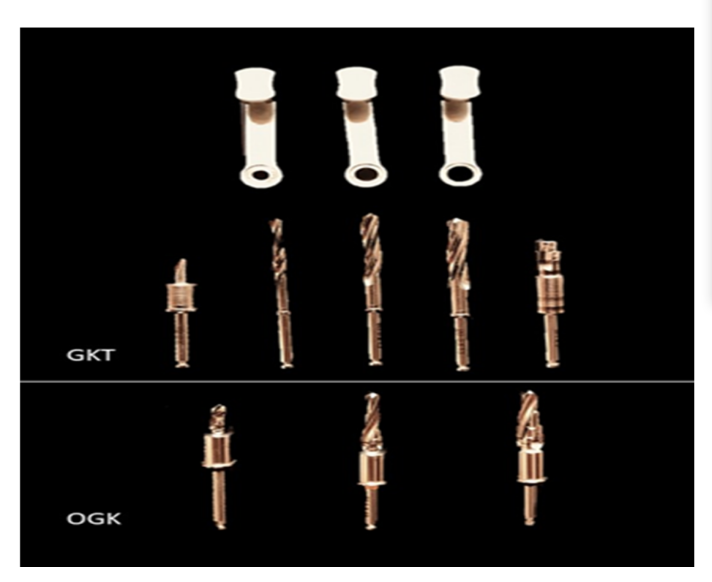

Time measurements were done with a digital stopwatch (iPhone 8, Apple Inc., Cupertino, CA, USA). The time period started after surgical template placement and finished upon removing the last drill. Time measurements were recorded in minutes, seconds, and hundredths of a second, and they were reported in Excel software (Microsoft Corporation, Redmond, Washington, DC, USA) by the same outcome assessor (M.C.). Measured times included the time needed to change the drills, and they were taken, independently, for every single implant site. All tools were stored in the kit and checked before each site preparation procedure. The drilling protocol required for implant site preparation (e.g., 4.0 mm diameter and 10 mm length) was as suggested by the manufacturer. Nevertheless, it was not equal in both surgical kits. For the sleeveless surgical guides (OGK), only three surgical drills were used, whereas, with the kit requiring metallic sleeves (GKT), five surgical drills and three metallic reductions (keys) were needed to prepare the site (Figure 8).

The comparison of preparation time was analyzed using Student’s t-test for independent samples (Statistica, StatSoft Polska, Cracow, Poland). A p-value < 0.05 was considered statistically significant. Results are shown as the mean ± standard deviation, and classic 95% confidence intervals were calculated.

Conclusions

Taking into consideration the results of this study with all its limitations, we can conclude that, using a 3D printed plastic-only guide with a dedicated OGK requires less time to prepare the implant site compared to using a plastic guide with an incorporated metallic sleeve and dedicated GKT surgical set. Metallic sleeves can be considered a safe aid for oral surgery. Therefore, anatomical structures are not damaged by their application. The shorter surgery time when using a 3D printed plastic-only guide becomes another clinically valuable factor in addition to to higher accuracy and lower production costs when compared to traditional, metal-sleeved templates. There have been many changes in the technology since 1992 when the era of digital implantology started. With the improvements of 3D printing technology and changes in guided drill design (from cylindrical requiring metallic sleeves incorporated into the template to protect the plastic guide part during drilling to tapered drills with a unified smooth guiding part), we can observe the evolution of digital implantology. Lower cost, higher accuracy and shorter surgery are the most important factors appreciated by clinicians, as well as by patients.

Łukasz Zadrożny, Marta Czajkowska, Marco Tallarico, Leopold Wagner, Jarosław Markowski, Eitan Mijiritsky and Marco Cicciù

References

- Mumoli, N.; Busoni, A.; Cei, M. A swallowed denture. Lancet 2009, 373, 1890.

- Bjertness, E.; Hansen, B.F.; Berseth, G.; Gronnesby, J.K. Oral hygiene and periodontitis in young adults. Lancet 1993, 342, 1170–1171.

- Bramanti, E.; Norcia, A.; Cicciù, M.; Matacena, G.; Cervino, G.; Troiano, G.; Zhurakivska, K.; Laino, L. Postextraction dental implant in the aesthetic zone, socket shield technique versus conventional protocol. J. Craniofacial Surg. 2018, 29, 1037–1041.

- Lavorgna, L.; Cervino, G.; Fiorillo, L.; Di Leo, G.; Troiano, G.; Ortensi, M.; Galantucci, L.; Cicciù, M. Reliability of a virtual prosthodontic project realized through a 2d and 3d photographic acquisition: An experimental study on the accuracy of different digital systems. Int. J. Environ. Res. Public Health 2019, 16, 5139.

- Ortiz, C.; Boyce, M.C. Materials science. Bioinspired structural materials. Science 2008, 319, 1053–1054.

- Laino, L.; Cicciù, M.; Fiorillo, L.; Crimi, S.; Bianchi, A.; Amoroso, G.; Monte, I.P.; Herford, A.S.; Cervino, G. Surgical Risk on Patients with Coagulopathies: Guidelines on Hemophiliac Patients for Oro-Maxillofacial Surgery. Int. J. Environ. Res. Public Health 2019, 16, 1386.

- Cicciù, M.; Fiorillo, L.; D’Amico, C.; Gambino, D.; Amantia, E.M.; Laino, L.; Crimi, S.; Campagna, P.; Bianchi, A.; Herford, A.S.; et al. 3D Digital Impression Systems Compared with Traditional Techniques in Dentistry: A Recent Data Systematic Review. Materials 2020, 13, 1982.

- Scrascia, R.; Fiorillo, L.; Gaita, V.; Secondo, L.; Nicita, F.; Cervino, G. Implant-Supported Prosthesis for Edentulous Patient Rehabilitation. From Temporary Prosthesis to Definitive with a New Protocol: A Single Case Report. Prosthesis 2020, 2, 10–24.

- Urban, I.; Caplanis, N.; Lozada, J.L. Simultaneous vertical guided bone regeneration and guided tissue regeneration in the posterior maxilla using recombinant human platelet-derived growth factor: A case report. J. Oral Implantol. 2009, 35, 251–256.

- Cicciù, M.; Cervino, G.; Terranova, A.; Risitano, G.; Raffaele, M.; Cucinotta, F.; Santonocito, D.; Fiorillo, L. Prosthetic and Mechanical Parameters of the Facial Bone under the Load of Different Dental Implant Shapes: A Parametric Study. Prosthesis 2019, 1, 41–53.

- D’Amico, C.; Bocchieri, S.; Sambataro, S.; Surace, G.; Stumpo, C.; Fiorillo, L. Occlusal Load Considerations in Implant-Supported Fixed Restorations. Prosthesis 2020, 2, 252–265.

- Tallarico, M.; Czajkowska, M.; Cicciù, M.; Giardina, F.; Minciarelli, A.; Zadroz˙ny, Ł.; Park, C.J.; Meloni, S.M. Accuracy of surgical templates with and without metallic sleeves in case of partial arch restorations: A systematic review. J. Dent. 2021, 115, 103852.

- Park, J.Y.; Song, Y.W.; Park, S.H.; Kim, J.H.; Park, J.M.; Lee, J.S. Clinical factors influencing implant positioning by guided surgery using a nonmetal sleeve template in the partially edentulous ridge: Multiple regression analysis of a prospective cohort. Clin. Oral Implant. Res. 2020, 31, 1187–1198.

- Zadrożny, Ł.; Czajkowska, M.; Mijiritsky, E.; Wagner, L. Repeatability of Freehand Implantations Supported with Universal Plastic Sleeves-In Vitro Study. Int. J. Environ. Res. Public Health 2020, 17, 4453.

- Tallarico, M.; Martinolli, M.; Kim, Y.; Cocchi, F.; Meloni, S.M.; Alushi, A.; Xhanari, E. Accuracy of Computer-Assisted Template-Based Implant Placement Using Two Different Surgical Templates Designed with or without Metallic Sleeves: A Randomized Controlled Trial. Dent. J. 2019, 7, 41.

- Marlière, D.A.A.; Demètrio, M.S.; Picinini, L.S.; Oliveira, R.G.; Netto, H. Accuracy of computer-guided surgery for dental implant placement in fully edentulous patients: A systematic review. Eur. J. Dent. 2018, 12, 153–160.

- Tallarico, M.; Caneva, M.; Baldini, N.; Gatti, F.; Duvina, M.; Billi, M.; Iannello, G.; Piacentini, G.; Meloni, S.M.; Cicciù, M. Patient-centered rehabilitation of single, partial, and complete edentulism with cemented- or screw-retained fixed dental prosthesis: The First Osstem Advanced Dental Implant Research and Education Center Consensus Conference 2017. Eur. J. Dent. 2018, 12, 617–626.

- Tahmaseb, A.; Wu, V.; Wismeijer, D.; Coucke, W.; Evans, C. The accuracy of static computer-aided implant surgery: A systematic review and meta-analysis. Clin. Oral Implant. Res. 2018, 29 (Suppl. 16), 416–435.

- Van de Wiele, G.; Teughels, W.; Vercruyssen, M.; Coucke, W.; Temmerman, A.; Quirynen, M. The accuracy of guided surgery via mucosa-supported stereolithographic surgical templates in the hands of surgeons with little experience. Clin. Oral. Implant. Res. 2015, 26, 1489–1494.

- Van Assche, N.; Vercruyssen, M.; Coucke, W.; Teughels, W.; Jacobs, R.; Quirynen, M. Accuracy of computer-aided implant placement. Clin. Oral Implant. Res. 2012, 23 (Suppl. 6), 112–123.

- Javaid, M.; Haleem, A. Current status and applications of additive manufacturing in dentistry: A literature-based review. J. Oral Biol. Craniofac. Res. 2019, 9, 179–185.

- Louvrier, A.; Marty, P.; Barrabé, A.; Euvrard, E.; Chatelain, B.; Weber, E.; Meyer, C. How useful is 3D printing in maxillofacial surgery? J. Stomatol. Oral Maxillofac. Surg. 2017, 118, 206–212.

- Tack, P.; Victor, J.; Gemmel, P.; Annemans, L. 3D-printing techniques in a medical setting: A systematic literature review. Biomed. Eng. Online 2016, 15, 115.

- Di Giacomo, G.; Silva, J.; Martines, R.; Ajzen, S. Computer-designed selective laser sintering surgical guide and immediate loading dental implants with definitive prosthesis in edentulous patient: A preliminary method. Eur. J. Dent. 2014, 8, 100–106.

- D’Souza, K.M.; Aras, M.A. Types of implant surgical guides in dentistry: A review. J. Oral Implantol. 2012, 38, 643–652.